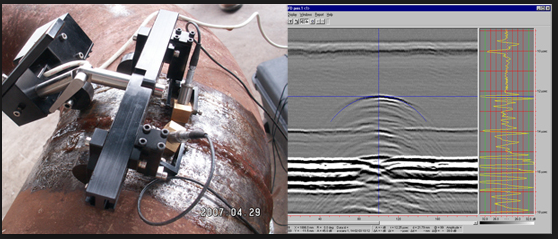

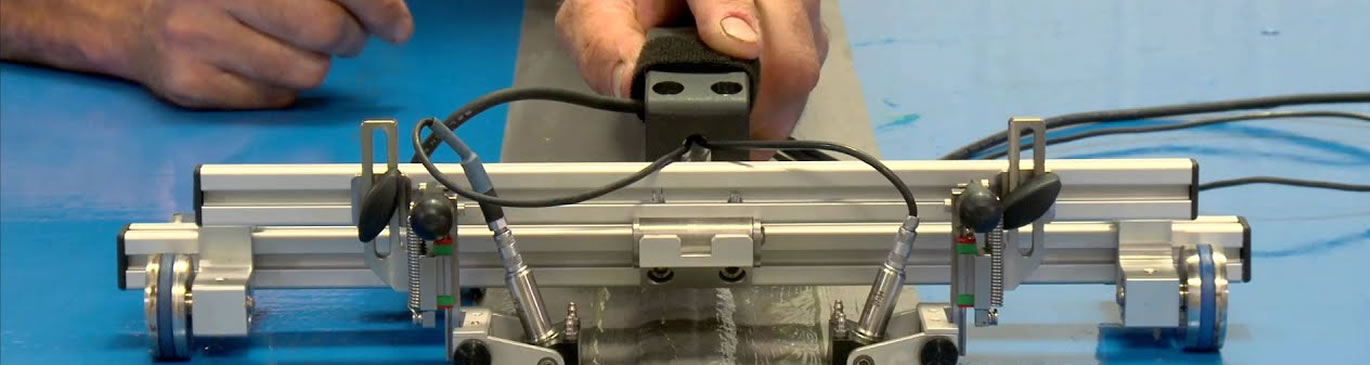

TOFD Utilizes diffracted energy in the detection of flaws; the technique is less reliant on flaw orientation and morphology than standard pulse echo techniques, leading to improved sizing and probability of defect detection (PPOD). Additionally, computerized electronic data capture and storage, in conjunction with scanning manipulators enable rapid scanning speeds to be achieved TOFD has now been accepted as an alternative to Radiography in Pre-Service Inspections with standards such as ASME 2235, and its use in pipe weld and thick walled pressure vessel fabrication is now common place.

TOFD Advantages :

- TOFD defect detection does not depend on the defect orientation, in contrast to the pulse echo technique.

- Defect height can be exactly determined, thus most suitable for monitoring growth or changes in known defects.

- Most efficient for inspection of thick-walled vessels where X & Gamma ray would re-quire too much time.

- TOFD method can be used to observe and report microscopic degradation caused by fatigue, stress and chemical attack – it has proven possible to quantify micro cracking caused by copper dilation through weld electrode contamination providing some knowledge of the probable fault mechanism is suspected prior to intervention.